About UI logic, support and layer height:

If you want to make it a little more simple (KISS), some thoughts:

The overstep function is great! Maybe you saw the Prusa edition of Slic3R, that able to define variable heights by had, also with a min and max. But you have to edit that min and max positions by hand. KS is now already 10 steps further. Now printing the first test.

Maybe now the relation between tabs is not so clear anymore.

What I would think: most people have a printer with a specific nozzle size. They almost never change it. I think the Pathwidth belongs to the printer profile and nozzle size. Some of my customers (and I) have more printers and they have different nozzle size mounted.

So maybe the base can be the nozzle size, pathwidth in the printer profile. Other nozzle size: than you make a new printer profile.

Belonging to that nozzle size in general: one can change the pathwidth a little: maybe +/- 25%.

The new overstep function is aiming at reducing the support structure. That's also dependent of the printer type and nozzle size.

IMO: to the printer profile and nozzle size there is a min layer height a printer/nozzle can print and a max layer height.

Most printers are capable to print layers from 0.05mm until 0.8mm depending the nozzle size.

With a certain nozzle size there is an optimum for layer height. FE with 0.4mm nozzle the min height is 0.1mm and the max 0.3mm

With a 0.2mm nozzle 0.05min and 0.15mm max

with a 1.0mm nozzle 0.2 min and 0.7mm max. It's often 25% of the nozzle size as min layer and 75% of the nozzle size as max layer.

I think that values belong to the printer tab.

Now, with that in mind I think the support tab can be invisible (not the raft / pillar / brim function, but the rest).

If so that would be much more KISS.

As you can define the generation of support because of settings of the min and max layer height regarding to nozzle size. For example a 0.4mm nozzle size.(or path width)

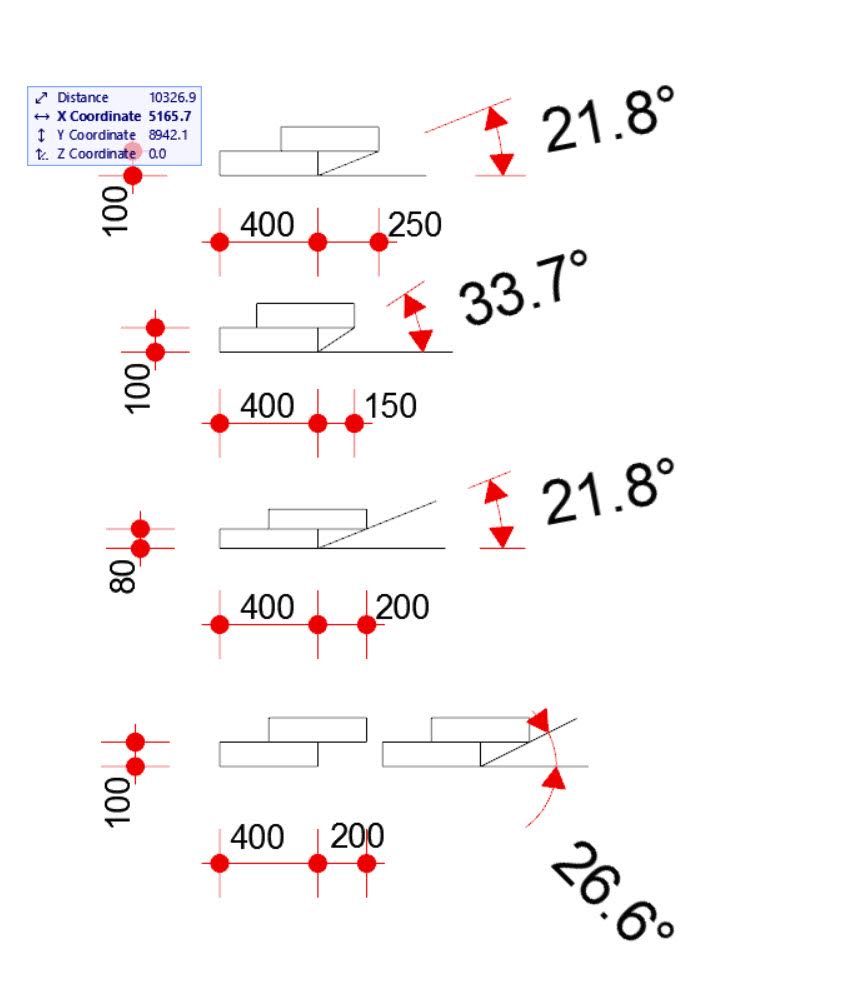

- unnamed (3).jpg (45.26 KiB) Viewed 2430 times

Given a min layer height there is a threshold were support needs to be generated. For example with 0.1mm min height it's needed from 37,6 degrees.

For all combinations between nozzle size (or path width) and the given min layer height there is an exact angle from were the support structure needs to be generated.

Free thinking: with that in mind the min and max layer height belong actually to the support tab, and not the style of printer tab.

So when using a switch on the style tab: using stepping over / var layer height or not : than on the support tab there are the original values visible, or the settings belong to nozzle size / path width and min / max layer height.

With dynamic layers / stepping over checked on the style tab only the basic functions remain as

skin thickness,

stacked layers

infill %

seam

I would add to it (and removing it from the support tab):

Brim settings

Prime pillar

Raft as check box, as the settings can stay on the support tab as they are to intense

For me: I would remove all the min max speed settings from the Printer tab / the slider on the style tab.

I would only put the speed settings on the style tab as they are, so:

perimeter speed

loop speed

solid infill speed

support speed

infill speed

travel speed

Z speed / raft speed etc can stay at the printer tab

The flow tweaks as they are also affecting speed still great on the material tab.

I'm happy to think further about it, when you think some make sense to reshuffle.

_____________________________________________

Anyway, with the above in mind and KISS:

The user downloads or make the obvious printer settings and forget it

with a specific nozzle mounted he adjust all on the support tab and forgets it

he downloads or set material values

And the important tweaks, switches, speeds are only to be set on the styletab.